-

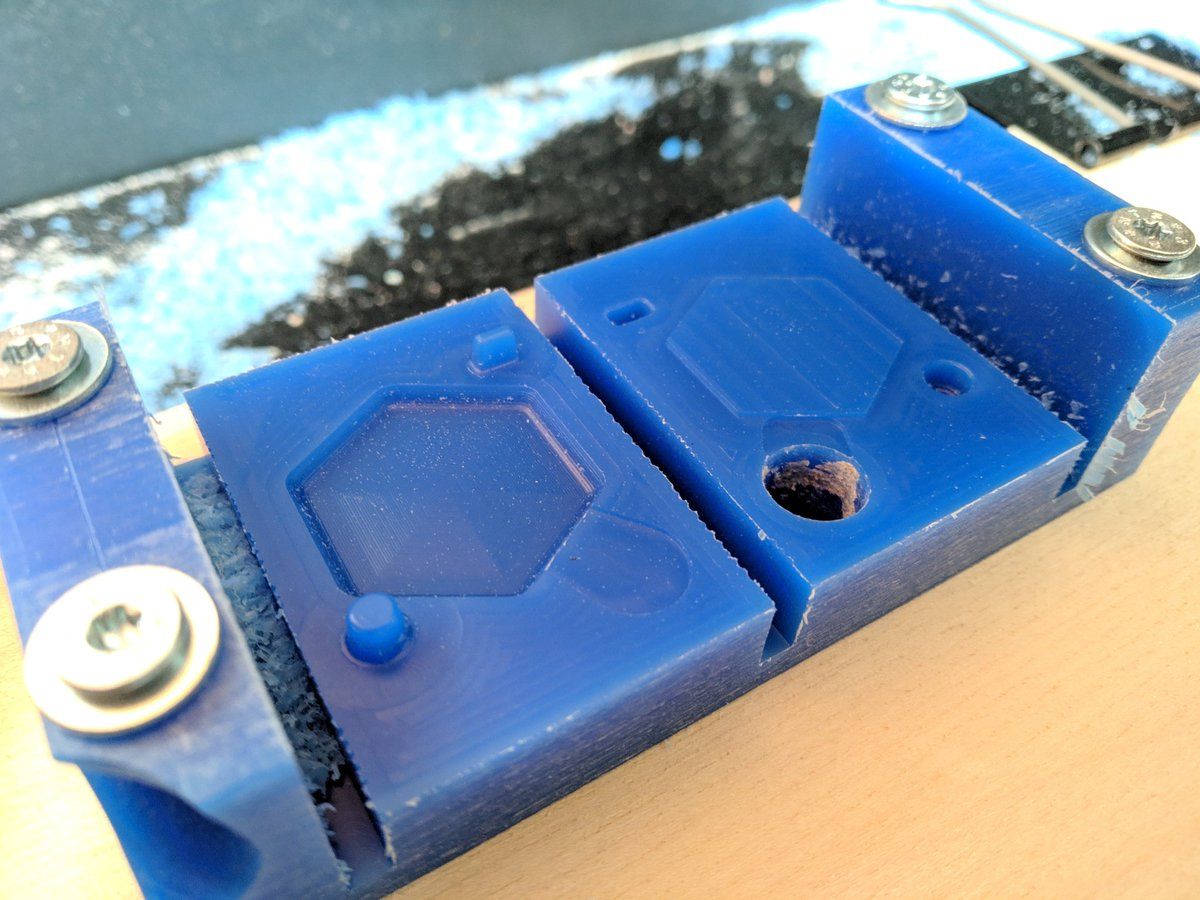

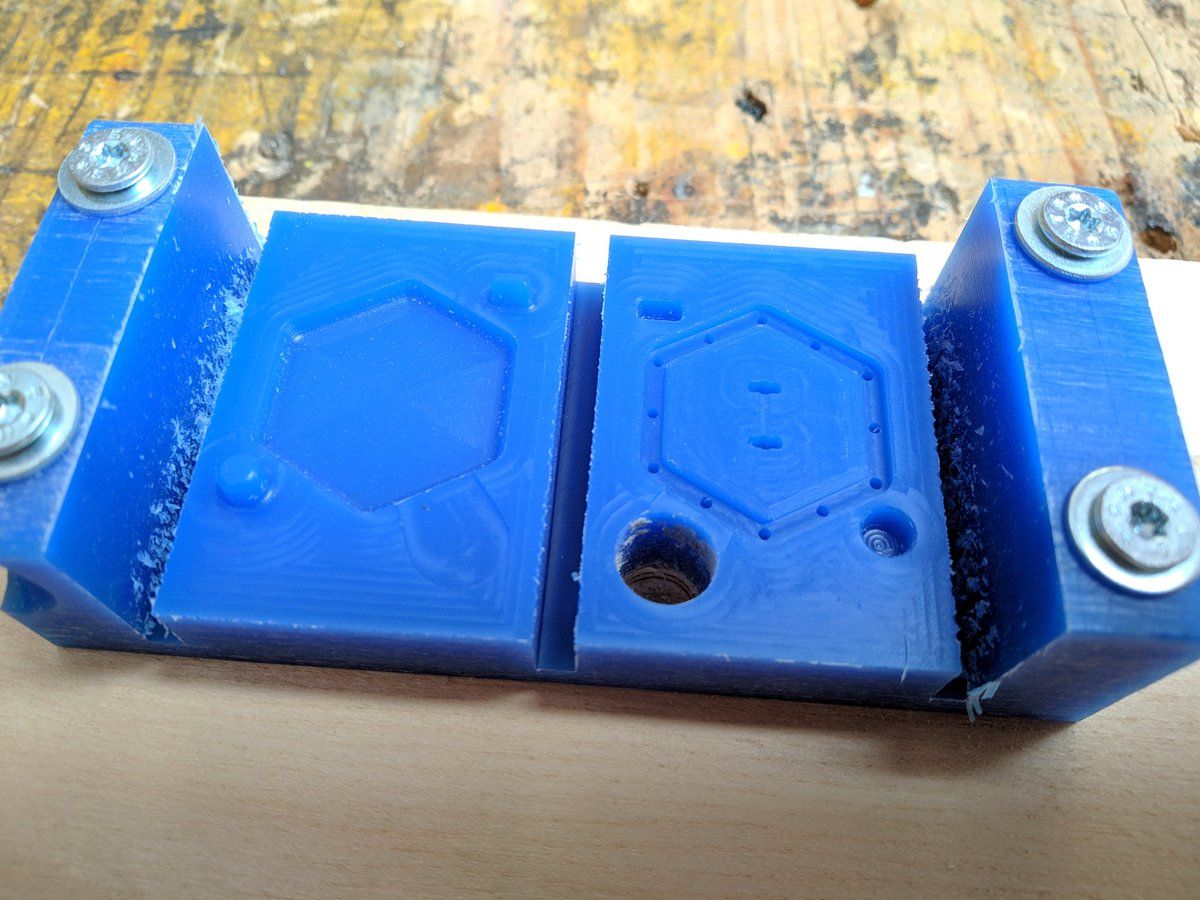

Milled a mold for hexagonal kailh choc keycaps today :)

-

The keycap and mold took one afternoon to design, another to adjust based on feedback from people who know how to make things, and then two more afternoons to learn enough CAM from them to make the toolpaths. Finally ~2h of milling and drilling ;)

-

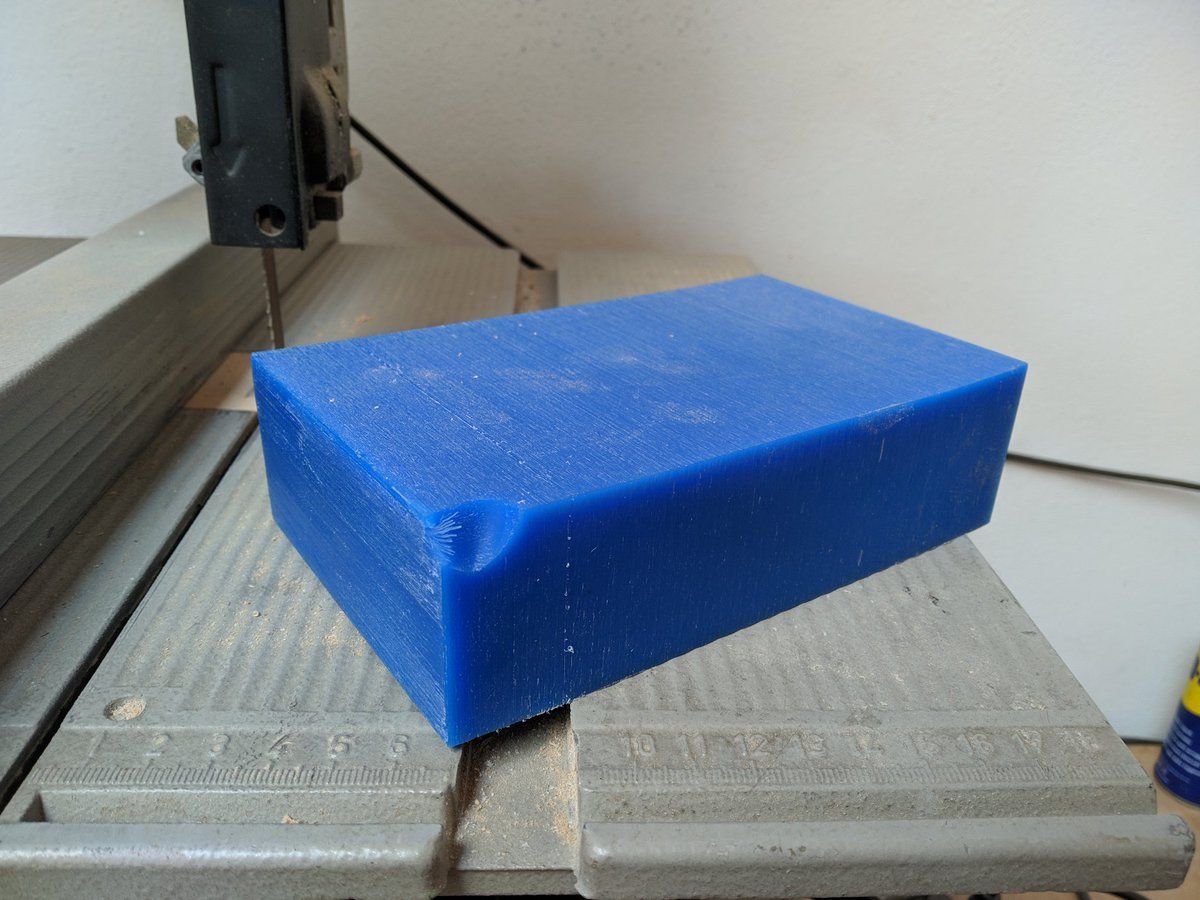

sanity-checking the program and zeroing

-

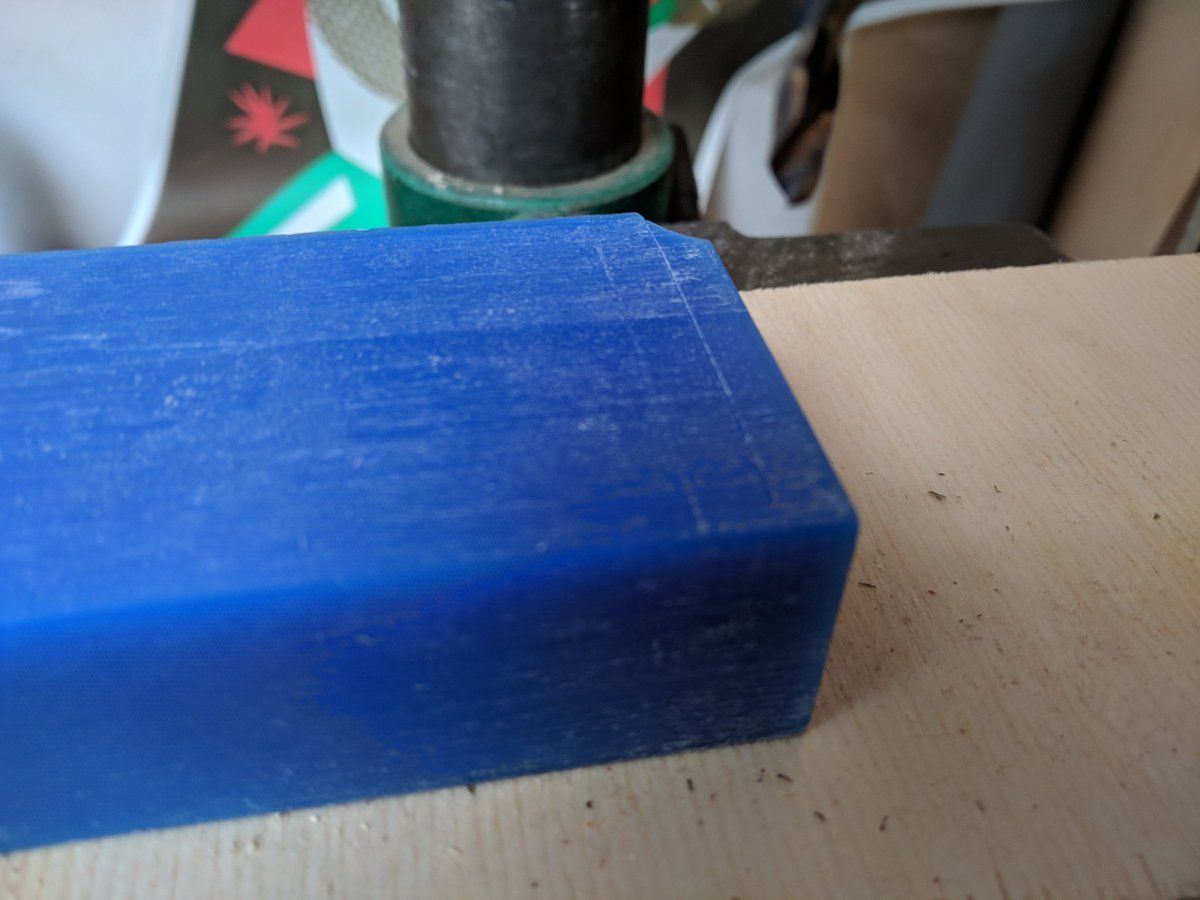

rough cut

-

-

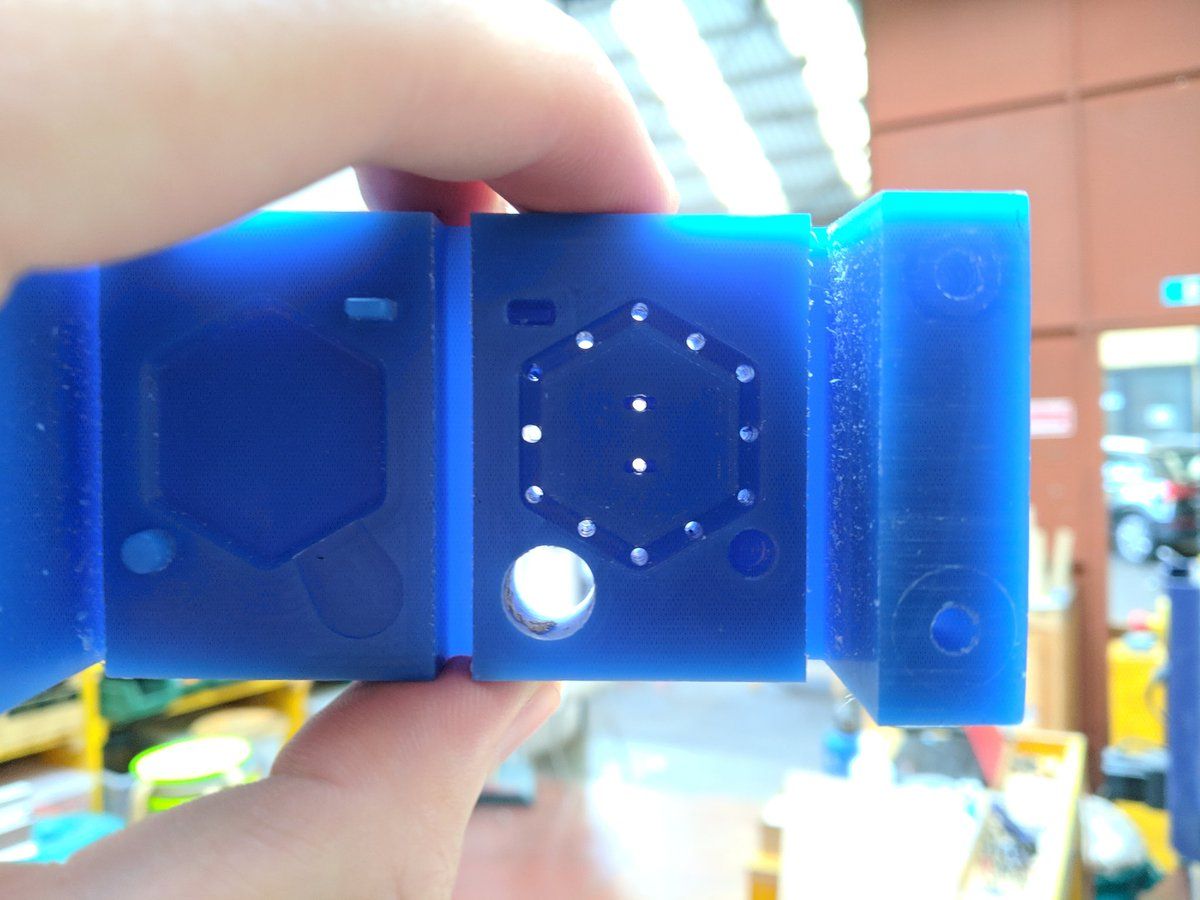

next finishing the details with a 1mm ball-end-mill

-

doesn't quite come across with the phone mic, but this sounded very satisfying with the different sounds for different angles and the rhythm becoming faster and faster

-

the other part continues with a 1mm flat endmill that can also mill out the two little teeth (that are only 1.2mm wide)

-

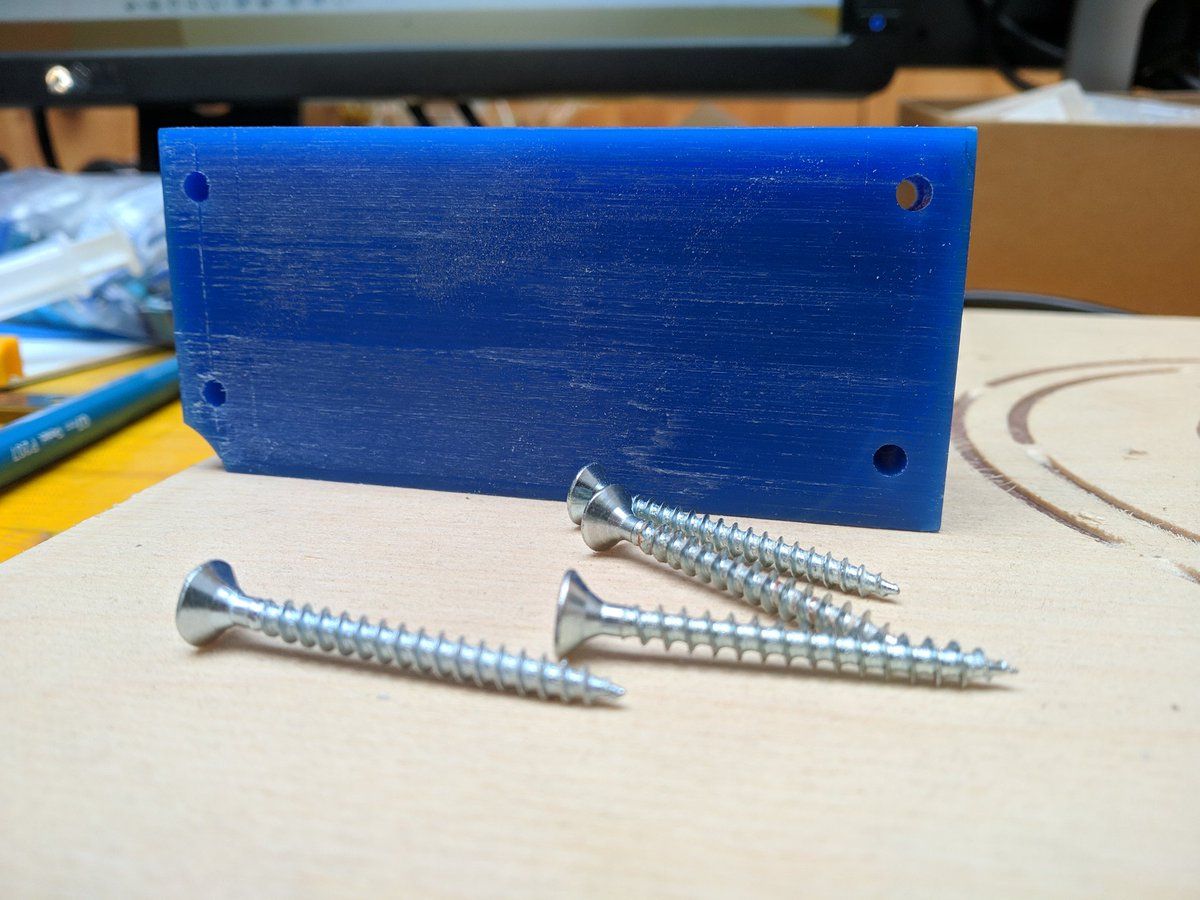

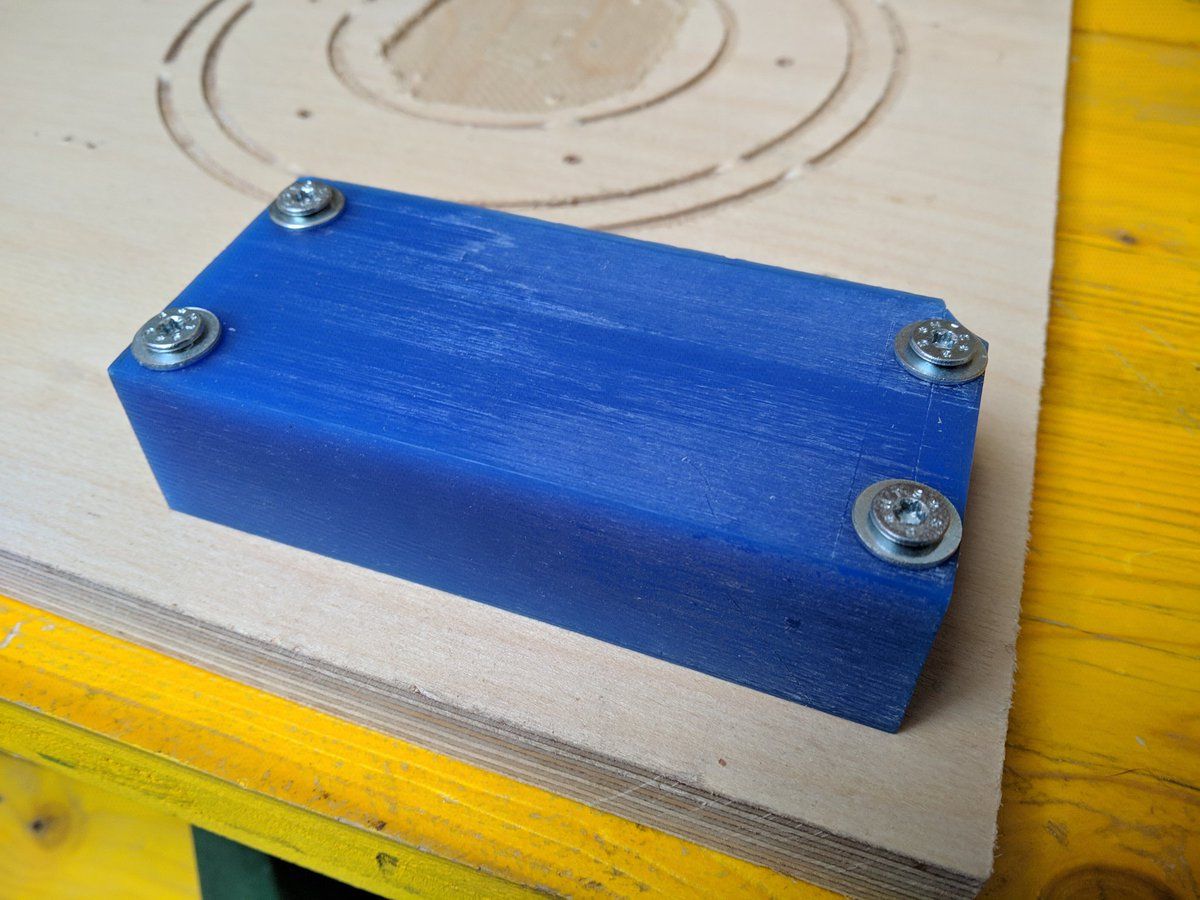

finally, (pre)drilling the vent holes. Since we don't have a long enough drill, these are just drilled a few mm down, I finished the rest by hand on the drill press (0.25mm clearance between drill and the wall i don't want to drill, that was terrifying!)